Luvata Welshpool Limited

Specializing in the design, prototyping and precision engineering of high-quality, customer specified components and assemblies, to the highest standard, on time and to budget

Luvata Welshpool (formerly Dawson Shanahan) is located in Welshpool, a market town in Wales that is approximately six kilometres from the Wales-England border. Our story began back in 1943 in precision engineering, starting out in automotive engine reconditioning. Since then, we’ve partnered with customers in almost every sector of industry – from automotive and motorsports to aviation, power distribution, electronics and medical.

What We Do

- Custom engineer components and assemblies

- Design, prototype and manufacture

- Engineer In: quality, performance and reliability

- Engineer Out: waste, inefficiency and cost

How We Do It

- Component design and prototyping

- Precision cold forming

- Precision CNC machining and turning

- Dedicated manufacturing cells, clean area production

Why Choose Us

- Excellence in precision cold forming and engineering

- Outstanding technical and commercial solutions

- Unrivalled engineering and applications knowledge

- Total quality assurance

Read more from Dawson Shanahan website

Precision Engineering Services

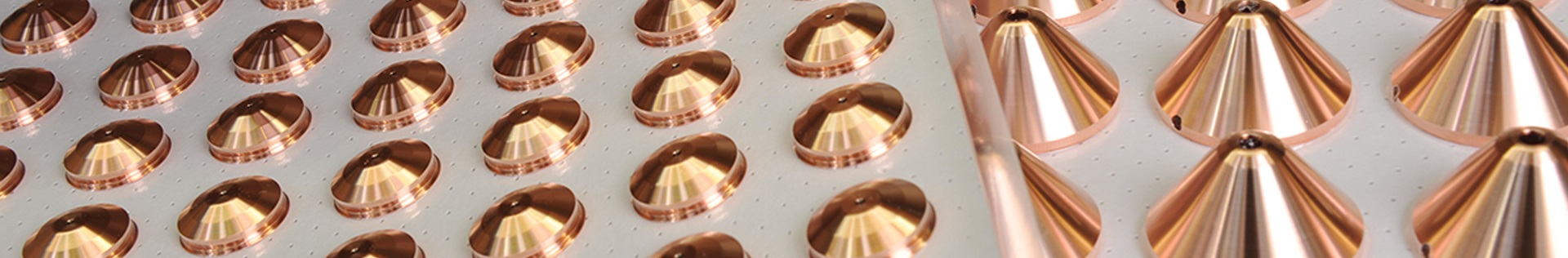

Precision Cold Forming – We can cold form in copper, aluminium and stainless steel

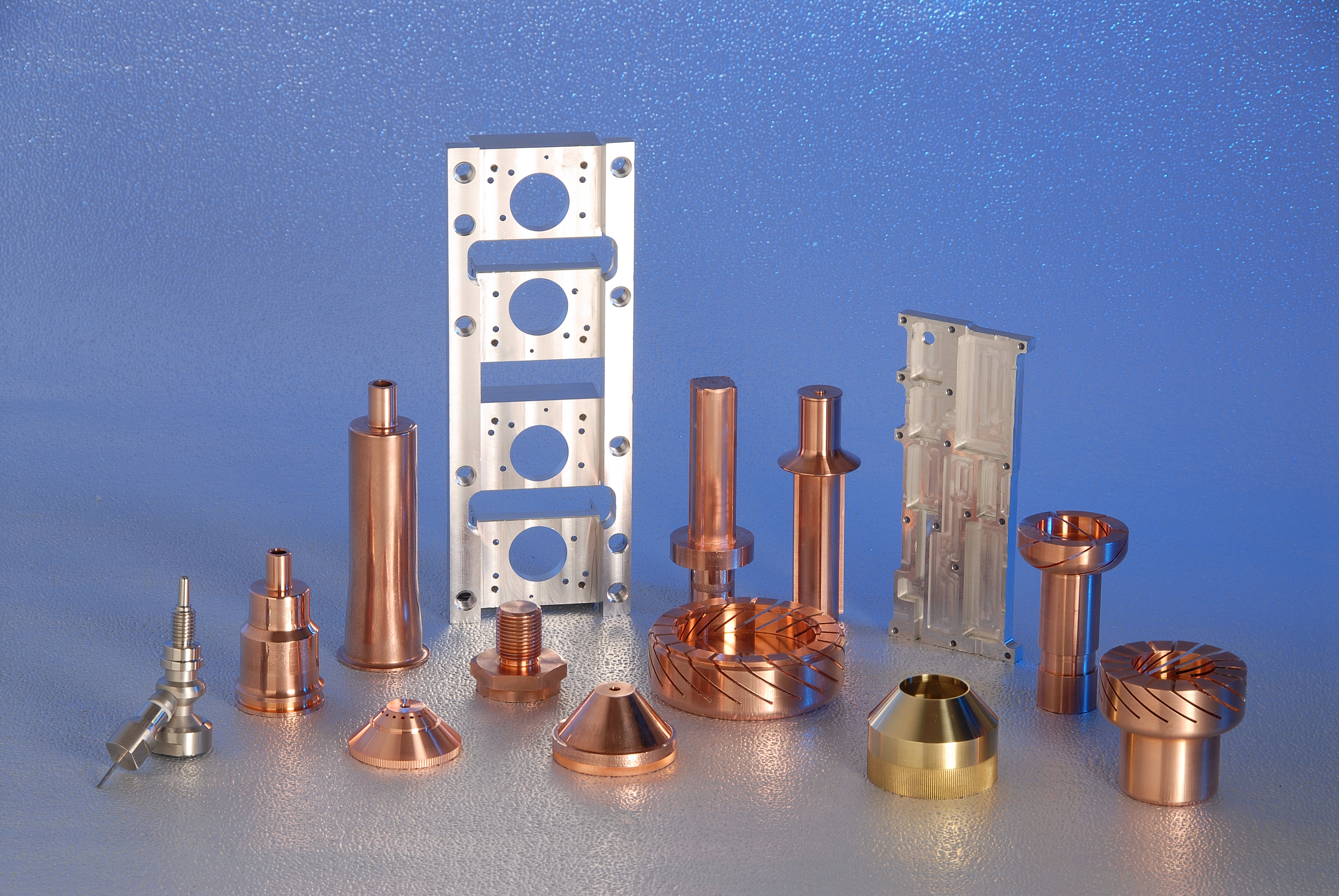

Precision CNC Machining – We specialise in precision CNC machining, turning and finishing, offering a full range of production options for customised components and assemblies

Assemblies – Luvata Welshpool can provide customers with a total solution under one roof, offering sub and complete assembly operations at our modern manufacturing facility

Copper Machining – We specialise in the copper machining of customer designed copper components, across a range of industries worldwide

Value Added Services – We can help you resolve the often-complex challenges of engineering components together with their assemblies as cost-effectively as possible

Tooling Design – Here at Luvata Welshpool we use the latest software systems, including DEFORM, the leading process simulation platform, to minimise development times, costs and complexity

Applications

Our extensive experience covers designing and manufacturing electrical and electromechanical connectors including crimp, plug, flat tail, tapped hole, and threaded post terminations, ensuring high-quality, reliable solutions tailored to your needs.

With over 80 years of experience in the aerospace sector, we specialise in manufacturing components for piston and jet engines, braking and undercarriage systems, flight surface controls, and cabin environment devices.

Our expertise in precision cold forming and machining enables engine, chassis, and drivetrain manufacturers for both cars and commercial vehicles to maximise the performance and efficiency of key components.

Precision, miniaturisation, quality, and traceability are crucial in manufacturing medical equipment components. We adhere to the highest standards, utilising dedicated clean rooms and production cells.

We provide high-power connectors made from oxygen-free, high-conductivity materials, essential for minimising power losses in generation and distribution applications.

By combining our cold forming and machining expertise, we ensure that production equipment such as lasers, plasmas, and welding systems will consistently deliver sub-micron accuracy.

Quality

Advanced Product Quality Planning (APQP) for seamless New Product Introduction / Product Launch and Product Insource:

- Product Design & Development – working with our customers to design and improve components to be optimized for functionality

- Process Design & Development – working with our customers to design and improve manufacturing routings that produce stable, repeatable parts whilst reducing costs and waste

- Product & Process Validation – data-driven product pedigree interrogation & reporting; data-driven process control and repeatability verification

- PPAP & PSW

- SPC & GRR

- Capacity Planning

- Continuous Improvement

- Supplier Auditing – control of our supply chain

- cGMP

We work to the highest quality standards to give you complete peace of mind. These include:

Interested in a Career at Luvata Welshpool?

If you’re interested in becoming one of our team and developing your skills further in an enjoyable and challenging environment, please take a look at our employment opportunities at Luvata Welshpool Careers page.

Les Reeves

-

les.reeves@luvata.com

Sarita Hernesniemi

+358 40 560 7008

sarita.hernesniemi@luvata.com