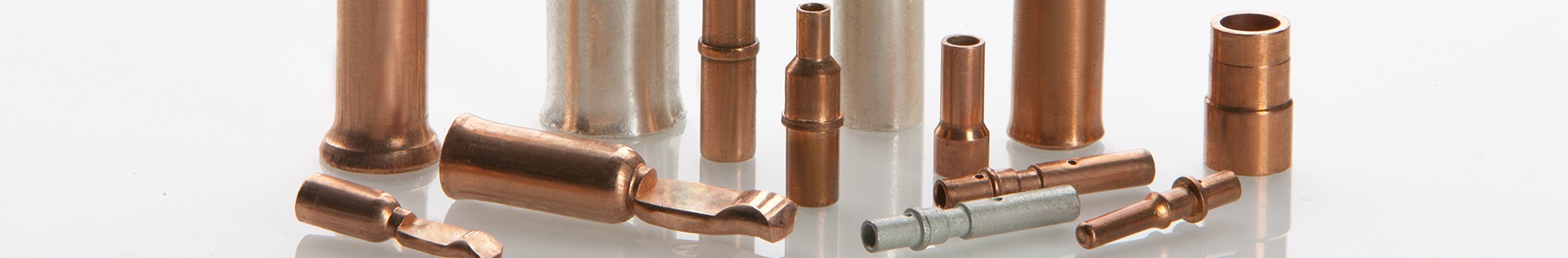

EV, PHEV & Industrial Connectors

Luvata’s cold-formed and Swiss machined copper and copper alloy connectors deliver performance, quality, and reliability.

Since 1960s, Luvata has been manufacturing copper connectors with exceptional cold-forming expertise and advanced copper alloys. Offering high voltage industrial connectors and low voltage connectors, socket bodies and pins, Luvata puts its metallurgical and cold-forming expertise into every connector. Today, our precision and complex connectors are widely used as electric vehicle connectors (EV Connectors), plug-in hybrid electric vehicle connectors (PHEV Connectors) and as industrial connectors, among other things.

Our connectors are customized specifically for customers’ needs. With our internally designed proprietary tooling and advanced cold-forming technique we make the exact connector for the exact need – with almost no scrap loss.

.jpg?sfvrsn=c69caa00_12)

EV Connectors & PHEV Connectors

Luvata is a reliable EV charging connector / charging inlet manufacturer with years of expertise. We produce high-quality copper connectors and contacts for the electric vehicle (EV) industry. Our connectors ensure efficient onboard charging, secure main battery connections, reliable switching for power and auxiliary systems, and safe power distribution within the Power Distribution Unit (PDU). Our polyamide PA12 coated busbars are used to transfer power from the charging inlets to the battery pack.

Our solutions include:

- AC charging pins / AC charging sockets

- DC charging pins / DC charging sockets

- DC charging inlets

- Copper contact bushings

- DC & AC interconnects

- Wire connectors

- DC & AC socket connectors

- EV charging connectors

- EV main drive cable end connectors

- EV components for contactor, battery interconnects and cell module connectors

- Terminal connectors and fuses

- Charging infrastructure connectors including crimp style solid copper connectors, slotted connectors, and pins for charging cables

Industrial high voltage connectors for power transmission

We offer custom-made power transmission connectors for industrial applications, including vacuum interrupters, high amperage and voltage industrial connectors, DIN connectors and flat blade slide connectors. Our solutions are made from high-quality oxygen-free copper, which offers low resistance, high conductivity and consistent properties. In addition to copper connectors, we offer solutions in other material options as well, like silver-bearing copper, Zirconium age-hardened alloy and Dispersion strengthened copper (DSC) and other copper alloys.

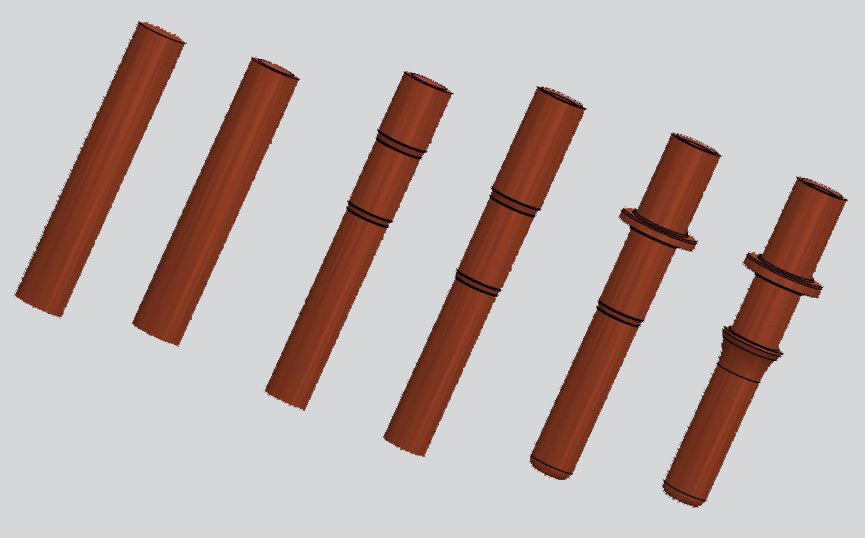

Cold-forming connectors

Luvata’s advanced cold-forming equipment and proprietary tooling designs are combined with our vertical integration of high-purity copper alloys. The proprietary tooling is internally designed by Luvata involving over a hundred components used in the most advanced cold-forming equipment available in the marketplace today.

This combination of tooling and cold-forming expertise offers Luvata customers many choices in delivering the exact product for the exact application, along with consistent quality, performance and reliability from the first connector to the last.

One of the biggest advantages of cold forming versus machining is that the typical Luvata customer experience has been 70 % reduction in scrap.

Advantages of cold-forming:

- Improved quality and product performance

- Cost savings with reduced process scrap

- Complex geometries with interior and exterior features

- Reduced processing times averaging one second per piece

- Reduced development costs and times

- Tooling cost saving

- Improved strength

- Complex geometries

Typical cold forming sequence for DC pin connector

- E-mobility, electric vehicles (EVs) and charging stations

- Oil and Gas

- Power distribution

- Renewable energy

- Vacuum interrupters

- EV main drive connectors, battery connectors, terminal connectors, fuses and cell module connectors

- Charging infrastructure connectors including crimp style solid copper connectors, slotted connectors and pins for charging cables

- High amperage industrial connectors, DIN and flat blade

Advantages of oxygen-free copper

Oxygen-free copper has a higher conductivity over tellurium (C14500) and sulphur copper (C14700), allowing for higher current carrying capability over these alloys without overheating.

If you are looking for nickel tin, nickel, silver or gold over molded terminal connectors or crimp style solid copper connectors for battery swapping or quick connect systems, we can help you. Barrel or rack plating is available for all parts.

Material options

- C10100

- C10200

- C11000

- C14500

- C14700

- C15000

- C18150

- C18200

- C19160

- C26000

- C35300

- C36000

- C97

- C96

- 1100 aluminum

- 6160 aluminum

- 1000 aluminum

- 6000 aluminum