.tmb-thum1920.jpg?Culture=en&sfvrsn=56c38288_12)

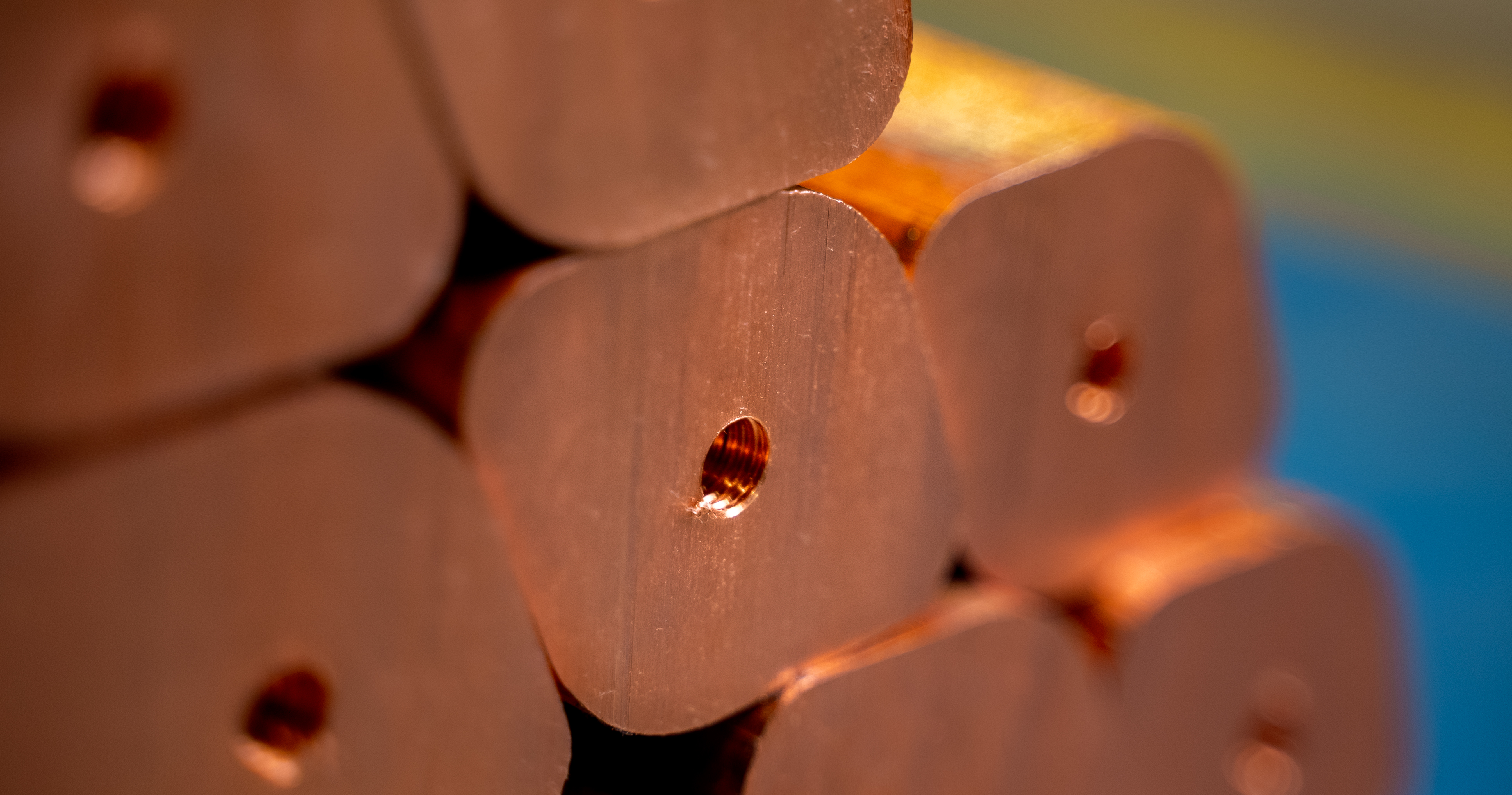

Copper anodes

Superior copper material for high plating efficiency

Electroplating is widely used in various industries for coating metal objects with a thin layer of a different metal. Electroplating can change the chemical, physical, and mechanical properties of an item, for example making it harder, stronger, or less corrosive. Luvata offers superior electroplating copper solutions, producing oxygen-free and phosphorous copper anodes with 50 years of expertise.

Luvata is a leading supplier of copper anodes for electroplating. Our copper anodes are manufactured from the purest electrolytically refined copper cathodes, which are melted under strictly controlled conditions to guarantee even alloying.

Each casting of both oxygen-free copper anodes and phosphorous copper anodes is made under highly controlled and optimum conditions. This leads to the lowest variation in structural and chemical properties and therefore predictable electrical conductivity, plating and ductility performance.

Our anodes have been designed to ensure low sludge development, stable copper content in plating, a rapid build-up of the adherent anode film to allow problem-free start-up of a new bath and a low build-up of impurities in the bath.

Benefits of copper anodes

At Luvata we have been manufacturing anodes for over fifty years, and we know that the quality of the copper anodes used is critical to a successful electroplating process. We use only high-purity copper, and our rigorous production process ensures consistent structural and chemical properties in every single anode. This ensures our customers of the reliable electrical conductivity, plating and ductility performance on which they depend.

Our high-quality copper anodes are reliable for their consistent coating thickness and performance. The benefits of Luvata anodes include:

- Ultimate high purity level

- Good dissolubility

- Even quality

- Full traceability

- Low tendency to passivation

- Low sludge development

- Low consumption of additives

Round and smooth ball anodes are very easy to handle as they are free flowing.

Each casting campaign of oxygen-free copper anodes or phosphorus copper anodes is made under highly controlled and optimum conditions. This leads to the lowest variation in structural and chemical properties and therefore high consistency of the end product. Luvata’s manufacturing process guarantees anodes to behave exactly the same way – from plating bath to bath.

Common applications include

- Coin blanks

- Rotogravure printing cylinders

- Printed circuit boards

- Decorative plating

- Radiators

- Automotive parts

Oxygen-free copper anodes

Oxygen-free copper anodes are manufactured from extremely pure copper. These anodes are used for the alkaline plating processes in cyanide and pyrophosphate baths.

Oxygen-free copper has no pores in the cast state and no copper oxide inclusions.

We have considerable expertise in electrochemical processes and works closely with both the chemical industry and plating line producers to continually improve products and production methods.

Phosphorous copper anodes

The phosphorous content of these anodes is P 0.04 - 0.06%. In our casting process, phosphorus is added to the master alloy which melts very fast. Due to diffusion and continuous movement of the copper melt, the phosphorous is instantly evenly distributed in the melt. This leads to even phosphorus content in each anode.

Our phosphorous copper anodes are widely used in the plating of printed circuit boards (PCBs) and in acid copper plating baths.

Forms

- Balls

- Slugs

- Mini-slugs

- Plates

- Ovals

- Hexagonals

- Dogbones

Luvata copper anodes come in different shapes and sizes, or they can be tailor-made to your specification.

Shapes

(All dimensions are mm; other shapes and sizes available upon request)

Balls | 15 25 28 40 50 |

| Slugs diameter | 8x15, 8x20 12x8, 12x10, 12x20 14x10, 14x20 25x25, 25x30-40 |

| Plates | 25 x 10 x L 100 x 10 x L 152 x 19 x L 175 x 15 x L |

| Ovals | 48 x 65 x L 51 x 76 x L |

| Dogbones | 94 x 34 x L |

| Hexagonals | 39 x 78 x L |

Examples of anode profile shapes

| Packaging | Sizes | Packaging type |

|---|---|---|

| Balls and Slugs | slugs all sizes; | 25 kg carton boxes on pallets max 1000 kg big bags on pallets |

| Balls | 40-50mm | 20 kg carton boxes on pallets |

| Plates and Profiles | 500/1000 kg | Bundles or wooden cases |

Several packing options are available: carton boxes on pallets, bundles and big bags